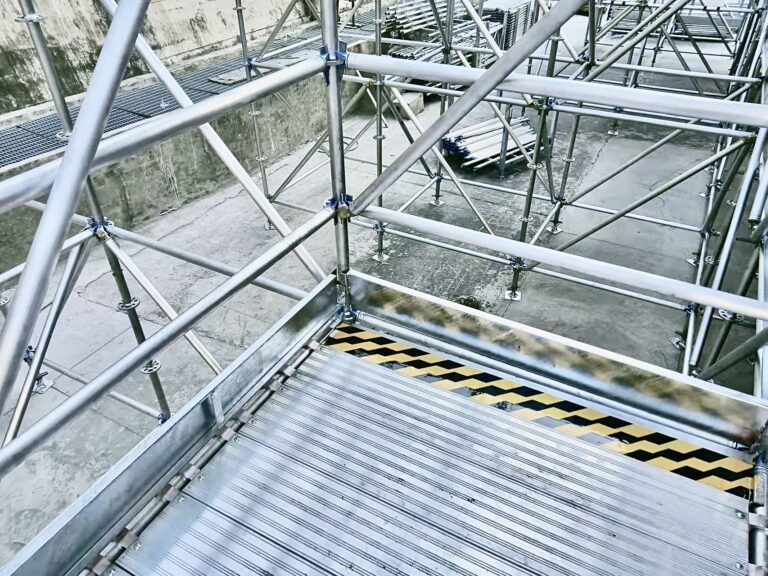

Premium Aluminum Ringlock Scaffolding System

20 years Aluminum Ringlock Scaffolding manufacturer in China. Custom any aluminum ringlock scaffolding based on your detailed requirement.

Lightweight and easy to carry,

All parts are corrosion resistant, good for long-time use.

Fast lock, fast install, save labor cost.

Best choice for high-rise building and chemical project.

OEM/ODM available.

Aluminum Ringlock Scaffolding Manufacturer in China

Scafotech is professional scaffolding manufacturer from China with over 20 years experience. We focus on light weight aluminum ringlock scaffolding system for construction, maintenance, and chemical site project.

We have strong design and engineering team, can support you 3D modeling service for your scaffolding project. Our aluminum ringlock scaffold is fast to assemble, easy to carry and install, safe for work at height. All our scaffolding meet international standards.

Our factory has 70,000m² area with full testing lab and product showroom. Welcome to visit our factory. We can offer you best custom scaffolding solution based on your detail requirements. 80% customers choose to order after visiting us.

What is Aluminum Ringlock Scaffold?

Aluminum Ringlock Scaffolding is a type of scaffolding system designed for versatility and strength. The term ‘Ringlock’ refers to the system’s unique connecting method that features a circular rosette or ‘ring’ at fixed intervals along a vertical or horizontal piece, known as a standard or ledger respectively. Components, including other standards, ledgers, and diagonal braces, are then secured to these rings using wedge-like connectors, hence ‘ring-lock’.

The ‘Aluminum’ part of Aluminum Ringlock Scaffolding refers to the material used in its construction. Aluminum 6082-T6 are chosen for its beneficial properties such as being lightweight, strong, and resistant to corrosion.

Because aluminum is anti-rust, this scaffold is good for wet area, food industry, chemical plant, or indoor high-rise building. Easy to carry, quick to install, and very safe for worker. Many customers choose aluminum ringlock scaffold because it is long life and easy to use.

Table Of Contents For This Page

It is not easy to introduce all aspects of Ringlock scaffolding, so we have prepared a lot of information on this page for you to delve into. To make sure you can find the information you want quickly, we have prepared this content directory that will jump to the corresponding location when you click on it.

General Applications For Aluminum Ringlock Scaffolding System

Ringlock scaffolding is an innovative, flexible, and secure system used widely in the construction industry. The system’s design and functionality allow it to adapt to a variety of construction projects, making it a popular choice for builders and contractors.

Use & Application Ringlock scaffolding is designed for multi-purpose applications, including building construction, civil engineering projects, and maintenance works. Due to its robust structure, it’s ideal for high-rise buildings, bridges, tunnels, and shipyards.

Setup & Installation Setting up Ringlock scaffolding involves three primary components: standards (verticals), ledgers (horizontals), and diagonal braces. The Ringlock system’s unique design allows these components to interlock securely using a ring and wedge connection mechanism. This setup not only facilitates rapid assembly and disassembly but also ensures structural stability and safety.

Functionality & Efficiency Ringlock scaffolding’s main strength lies in its functionality and efficiency. It’s designed to be lightweight yet sturdy, allowing for easier handling and reduced labor during installation and removal. The system also allows for various configurations, making it adaptable to the specific needs and constraints of a project, whether it involves complex geometries or challenging working conditions.

Safety Standards Ringlock scaffolding sets a high bar when it comes to safety. Its unique ring and wedge connection design ensures a secure lock, providing a stable platform for workers. The sturdy structure of Ringlock scaffolding makes it resistant to harsh weather conditions, adding an extra layer of security on site.

Durability and Maintenance Crafted with high-strength steel, Ringlock scaffolding is designed for longevity. It resists corrosion and wear, thus requiring less maintenance over time. This durability makes Ringlock scaffolding a cost-effective choice, reducing the frequency of replacements and repairs.

Versatility and Adaptability Perhaps the most defining feature of Ringlock scaffolding is its adaptability. The system can be configured in multiple ways to accommodate various project needs. Be it a high-rise building, a complex bridge structure, or a confined tunnel project, Ringlock scaffolding caters to diverse construction scenarios.

Efficient Assembly Ringlock scaffolding streamlines the assembly process. The simple yet secure ring and wedge connections make it easy to assemble, dismantle, and transport, resulting in significant time and labor savings.

Understanding how to correctly use and install Ringlock scaffolding is essential for maximizing its benefits and ensuring safety on the construction site. By choosing a scaffolding solution that is versatile, reliable, and easy to use, construction projects can become more efficient, cost-effective, and safer.

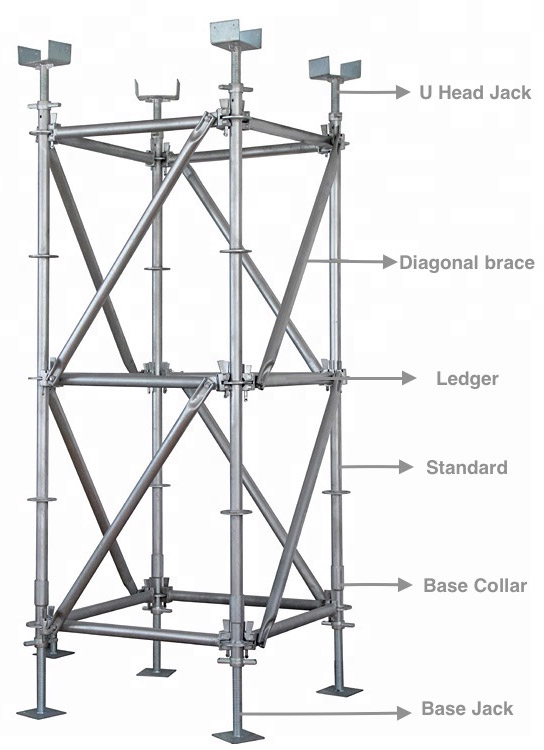

Aluminum Ringlock Scaffold Components

Delve into the world of construction’s popular choices with the key components of Aluminum Ringlock Scaffolding. These integral parts of the system have been flying off the shelves, resonating with professionals for their efficiency, safety, and adaptability.

Aluminum Ringlock Scaffolding Standards / Upright / Vertical

- Premium Aluminum 6082-T6

- Mill Finish

- High Quality Ensures

- TUV, SGS Certifications

The backbone of any Ringlock system, standards form the vertical element of the scaffolding. High-strength and durable, they ensure the scaffolding remains robust and stable throughout its use.

Aluminum Ringlock Scaffolding Ledgers

- Premium Aluminum 6082-T6

- Mill Finish

- High Quality Ensures

- TUV, SGS Certifications

As the horizontal component, ledgers provide critical support to the working platform. Their easy connection to the standards contributes to the overall safety and stability of the system.

Aluminum Base Collars

- Premium Aluminum 6082-T6

- Mill Finish

- High Quality Ensures

- TUV, SGS Certifications

These components serve as the starting base for the scaffolding, allowing for the connection of the standards and ensuring a secure and stable foundation.

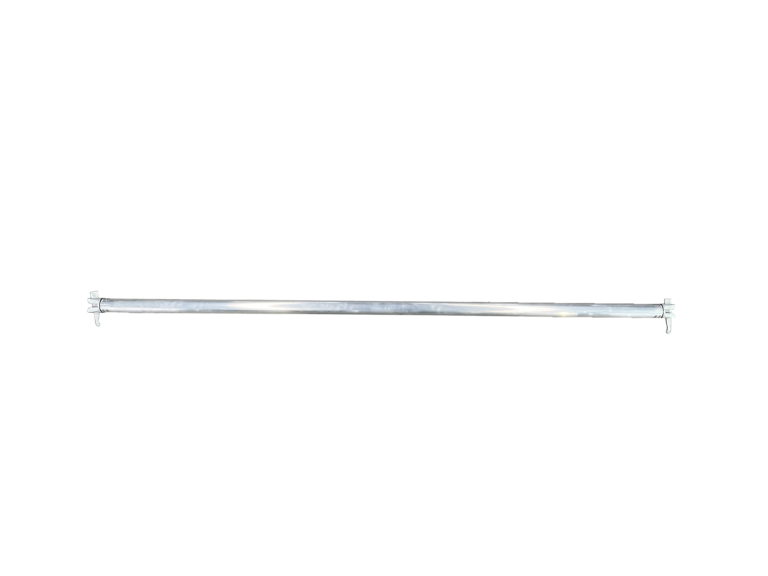

Aluminum Ringlock Diagonal Brace

- Premium Aluminum 6082-T6

- Mill Finish

- High Quality Ensures

- TUV, SGS Certifications

These components enhance the scaffolding’s rigidity, ensuring structural integrity under various load conditions. Their contribution to system stability makes them a sought-after piece in any Ringlock Scaffolding setup.

These hot-selling components are what make Aluminum Ringlock Scaffolding such a versatile and reliable choice in the construction industry. Their design ensures easy assembly and disassembly, providing an efficient and cost-effective scaffolding solution. Discover the difference that high-quality Ringlock Scaffolding components can make in your next project.

Packing & Certifications For Ringlock Scaffoding

At ScafoTech, we are committed to delivering not just top-tier scaffolding solutions but also unrivalled customer experience. We know the safety of your workers and the success of your project rely heavily on the quality and reliability of our products. That’s why every piece of our Ringlock Scaffolding comes with industry-leading packing and internationally recognized certifications.

Our meticulous packing process ensures the integrity of your scaffolding during transit, keeping it safe from environmental hazards and ensuring it arrives at your site in perfect condition, ready for immediate installation.

In terms of certification, we proudly comply with international standards, as reflected by our TUV, SGS, OSHA, and ANIS certifications. These certifications are proof of our commitment to safety, quality, and global best practices, giving you confidence and peace of mind when choosing ScafoTech.

Choose ScafoTech for your Ringlock Scaffolding needs. Experience the assurance of excellent packing, certification, and a partner who puts your project’s success at the heart of our business. Connect with us today and let us help you build tomorrow’s landmark with confidence.

The Process Flow & Duration Estimation

Your Journey with ScafoTech’s Aluminum Ringlock Scaffolding: Step by Step Process & Time Estimation:

On average, the complete process from project assessment to shipping takes about 20-30 days, providing you with a seamless and efficient experience. Choose ScafoTech, where we align our processes with your schedule, because we know time matters. Start your scaffolding journey with us today!

Step 1: Project Assessment (1-3 days)

The process begins with understanding your project requirements. We thoroughly assess your plans, building codes, and specific needs to ensure our Ringlock Scaffolding system is the perfect fit for your project.

Step 2: Design Phase (5-7 days)

Our experienced engineers employ advanced CAD software to craft a custom scaffold design that aligns with your project specifications, focusing on safety, functionality, and efficiency.

Step 3: Manufacturing (10-14 days)

Upon design approval, our factory springs into action. High-quality materials are transformed into durable, reliable components of the Ringlock Scaffolding system, each subject to rigorous quality checks.

Step 4: Packing and Quality Assurance (2-3 days)

Every piece of your Ringlock Scaffolding is properly packed and inspected again, ensuring they are ready for safe transport and immediate installation upon arrival.

Step 5: Shipping (Varies)

Working with reliable logistics partners, we orchestrate the shipping process. Delivery times can vary depending on your location, but we ensure optimal speed without compromising the safety of the products.

Please note that the final cost depends on the customized service you require, the specifications of the raw materials used, the relevant national laws, and the distance of transportation.

Want to know how to compress lead times?

Choose our aluminum ringlock scaffolding — fast lock design, quick assembly, and ready-to-ship stock help you finish project faster!

The Basic Knowledge About Ringlock Scaffolding

What is Aluminum Ringlock Scaffolding?

Dive into the world of Aluminum Ringlock Scaffolding – a game-changer in the construction, entertainment, and shipbuilding industries. This state-of-the-art scaffolding system is renowned for its unique ‘ringlock’ connection method. Featuring a circular ‘ring’ at fixed intervals on a vertical or horizontal component, other scaffolding elements can be securely locked into place, offering unmatched versatility and strength.

Built with high-quality, corrosion-resistant aluminum, our Aluminum Ringlock Scaffolding system brings together the best of all worlds. Enjoy the lightweight convenience that makes transport and handling a breeze, coupled with the outstanding strength and durability that ensures a reliable, secure structure. Experience the added benefit of low maintenance, thanks to aluminum’s resistance to rust.

Explore the capabilities of our eco-friendly Aluminum Ringlock Scaffolding – designed for performance, durability, and sustainability. A solution that meets all your scaffolding needs while paving the way for a greener future.”

Ringlock scaffolding, also known as modular scaffolding, is a type of scaffolding system that is widely used in construction, entertainment, shipbuilding, and many other industries. The system is named “ringlock” because it features a ring with wedge slots at regular intervals around it, which is the key element that allows various components to be connected together.

Here’s a brief overview of the main components of a ringlock scaffolding system:

Standard or Vertical: This is the vertical component with the aforementioned ringlock at regular intervals. It serves as the main structural support for the scaffolding.

Ledger or Horizontal: This is the horizontal component that connects the standards. It provides lateral support to the scaffolding structure.

Diagonal Brace: This component connects the standards diagonally, providing additional stability and rigidity to the structure.

Base Collar: This component is placed at the base of the standard to allow ledgers and braces to connect at ground level.

Plank or Decking: These components create the working platform for workers to stand on.

Guardrail: This is a protective barrier placed on the outer edges of the platform to prevent falls.

When it comes to Aluminum Ringlock Scaffolding, the main difference lies in the material used. As the name suggests, it’s made from high-strength, lightweight aluminum, which offers several advantages such as:

Lightweight: Aluminum is much lighter than traditional steel scaffolding, making it easier to transport and handle on-site.

Corrosion-resistant: Aluminum does not rust, giving it a longer lifespan and reducing maintenance needs.

Strong and Durable: Despite being lighter, aluminum scaffolding maintains a high load-bearing capacity and durability.

Eco-friendly: Aluminum is recyclable, making it a more environmentally friendly option compared to some other materials.

Therefore, Aluminum Ringlock Scaffolding is a versatile and efficient choice for many different applications, combining the flexibility of the ringlock system with the advantages of aluminum as a material.

The Common Pitfalls When Purchasing

Purchasing scaffolding for import from China or any other country involves several key considerations and potential pitfalls to be aware of. Here are some points that customers should pay attention to:

Quality Assurance: It’s crucial to ensure that the scaffolding is manufactured to international safety standards and has undergone rigorous quality control checks. Ask for relevant certifications to confirm that the product is compliant with your country’s regulations.

Reliability of Manufacturer: Conduct due diligence to confirm the reliability of the manufacturer. Check for business license, history, financial stability, previous customer reviews, and any potential red flags.

Communication: Clear communication is key in international trade. Ensure that the supplier understands your specific requirements, deadlines, and terms of delivery.

Pricing: While everyone seeks a good deal, be wary of prices that seem too good to be true. They often are, and you may end up with subpar goods or complications in delivery.

Shipping and Logistics: Understand the terms of delivery (Incoterms) to know who’s responsible for shipping, insurance, and duties. Check for any hidden costs that could increase the total cost of importing the scaffolding.

Contract: Make sure to have a clear and detailed contract outlining terms, product specifications, payment terms, delivery timelines, and dispute resolution mechanisms.

Import Regulations: Be aware of the import regulations and tariffs in your country for importing scaffolding. Any violations can lead to fines or delays in customs.

Samples and Inspection: Before placing a large order, it can be beneficial to purchase a sample or hire a third-party inspection company to verify the quality of the scaffolding.

Payment Terms: Be cautious with payment terms. It’s advisable to use a secure payment method or a letter of credit to safeguard your interests.

After Sales Service: Consider the manufacturer’s warranty policy and after-sales service. This will be particularly helpful if any issues arise with the product after purchase.

Purchasing scaffolding from overseas, particularly from China, can be cost-effective but also comes with potential risks. Hence, it’s important to be thorough in your research, planning, and communication.

A Brief Self-Nomination, Why Choose Scafotech?

At ScafoTech, we specialize in providing high-quality scaffolding, formwork systems, and building materials to clients worldwide. With over 20 years of experience in the industry, we have built a reputation for delivering custom-made products that meet the specific needs of our clients. Our team of 300 skilled workers is dedicated to providing engineering solutions and developing innovative new products. We offer excellent customer service, competitive pricing, and comprehensive warranties to ensure our clients receive the highest level of quality and safety. Contact us today to learn more about how we can help you with your scaffolding and formwork needs.

The FAQs About ScafoTech

How large is the work shop?

First phase investment of approximately RMB 40 million. It covers 20,000 square meters, in which building area covers 13, 000 square meters.

How much is the annual production capacity of Scafotech Scaffolding?

40, 000T/year.

When can I get the quotation after the inquiry?

Within 12 hours after you send the mail.

What is the delivery time?

Generally speaking, 30-45 days after receiving the prepayment.

Can Scafotech provide samples?

Yes. If the sample is common and in small quantity it is free. If the sample is uncommon and in different kinds, it will be charged.

What′s the quality managing system?

Scafotech has passed the ISO international quality certificate and EN cetifications.

Does Scafotech design and develop new products?

Scafotech takes pride in offering a team of highly experienced and suitably qualified engineering and technical experts. We can design and make new products according to your requests.

How to store the scaffolding?

For scaffolding which finish is EP, PC and painted, it is recommended to store in ventilated and dry room. For scaffolding which finish is HDG, there is no special requirements.

How long is the lifespan of your products?

The lifespan of the hot-dipped galvanized products is about from 10 to 15 years, depending on the specific situation.