Aluminum Ringlock Scaffolding Components

Scafotech is the top Aluminum Ringlock Scaffolding manufacturer in China. If you are looking for aluminum standards, aluminum Ledgers, aluminum Base Collars, aluminum diagonal braces, Aluminum Lattice Girders, etc. Scafotech is your first choice , we can custom any aluminum ringlock scaffolding according to your requirements or drawing.

Aluminum Ringlock Scaffold Parts

Material: Aluminum 6082-T6

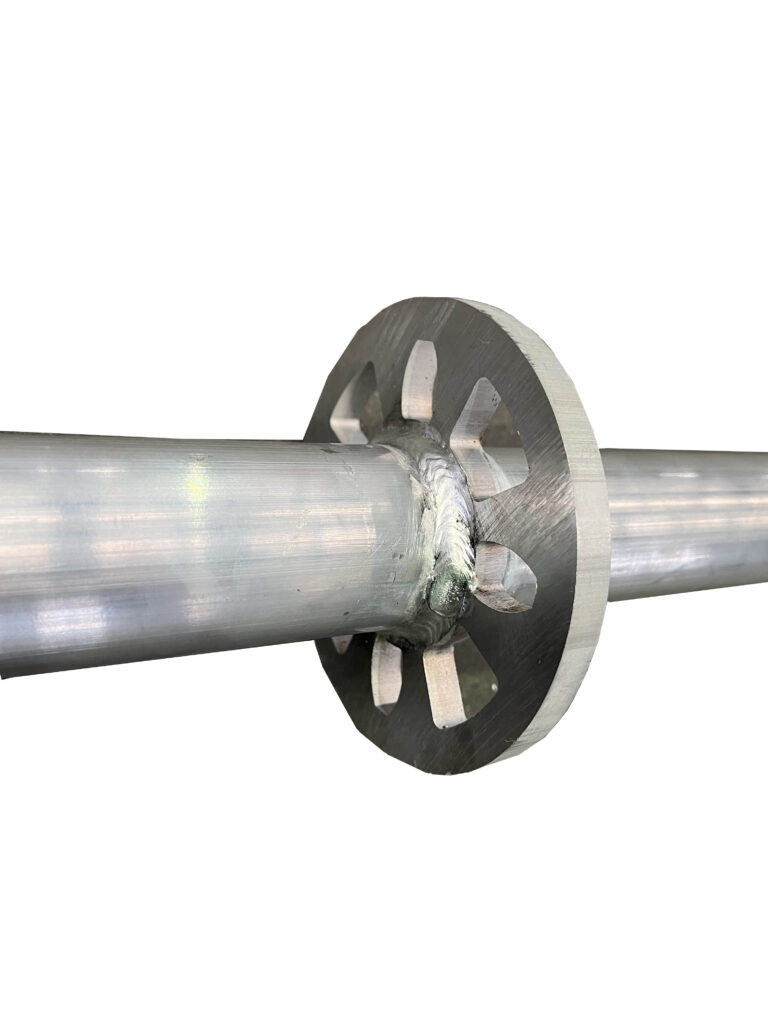

Aluminum Ringlock standards are vertical parts in the ring system. Sizes 0.5m to 4m. The standard includes rosette rings at 50cm intervals. There are OD48.3mm and OD60mm ringlock standards.

Material: Aluminum 6082-T6

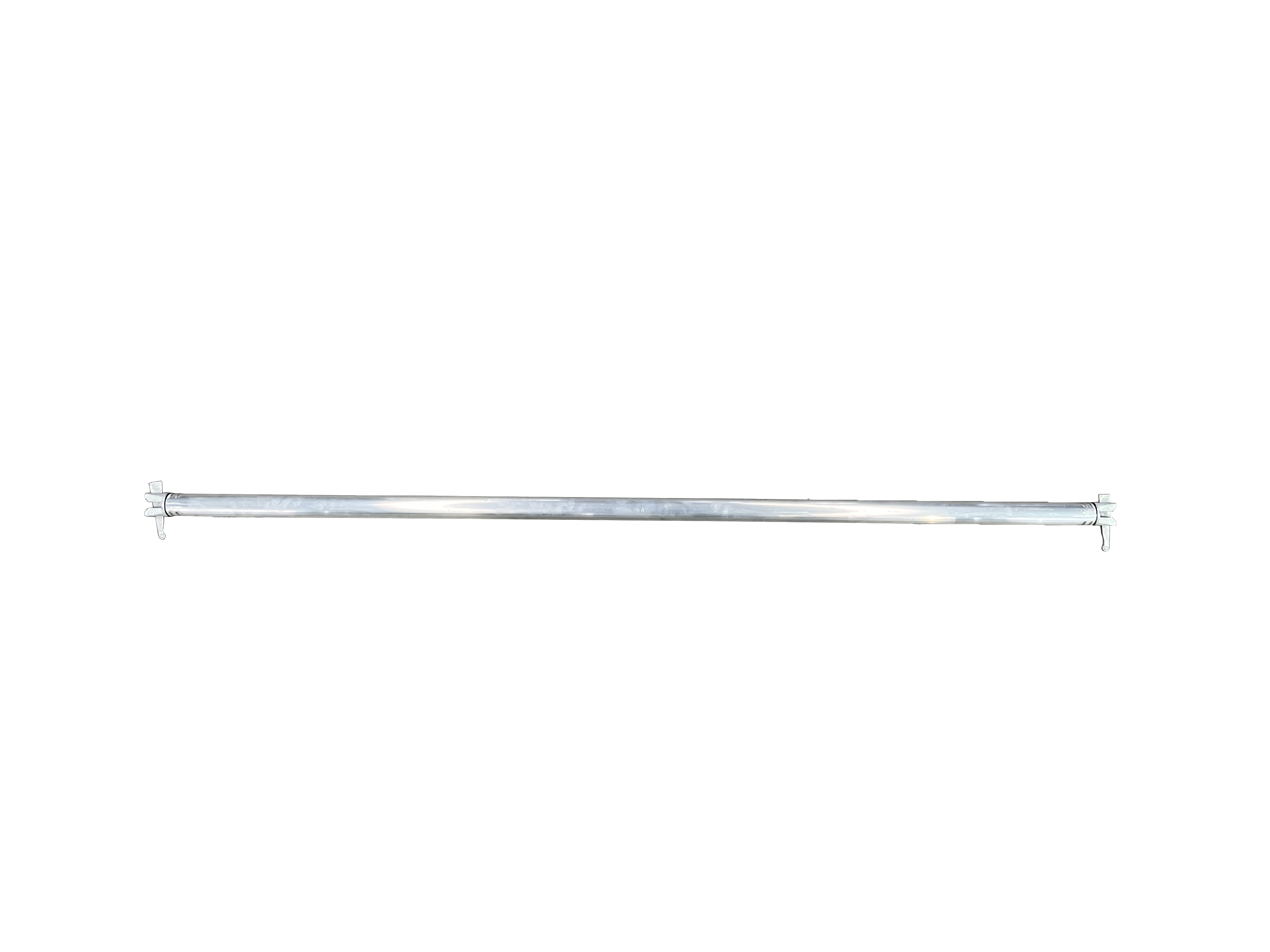

Aluminum Ringlock ledger is typical horizontal parts made from OD48.3mm scaffold tubes. It includes ledger heads and wedge pins on both sides. The ledger headsets connect to the ring lock standard rings in erect.

Material: Aluminum 6082-T6

Aluminum Ringlock scaffolding diagonal brace makes the ring lock system tower bay stable and strong. It is with two sets of brace heads. Brace sizes are versatile according to horizontal sizes and vertical distances.

Material: Aluminum 6061-T6

Aluminum Toe Board, the ultimate solution for enhancing safety and stability on your scaffolding projects. Crafted from high-grade aluminum, this lightweight yet durable toe board is designed to prevent tools and debris from falling, ensuring a secure work environment. Its easy-to-install design makes it a practical addition to any scaffolding system, offering unmatched protection without compromising on efficiency.

Material: Aluminum 6082-T6

Aluminum base collar is also called a starter in the ring lock system. We custom for you different sizes of base collars from 240mm to 410mm. You can choose the right base collar size for construction or staging.

Choose the right base coupler for your project: Aluminum for lightweight, corrosion-resistant ease of use, or Steel for cost-effective, heavy-duty support. Each offers unique benefits to meet diverse construction needs.

Material: Aluminum 6061-T6

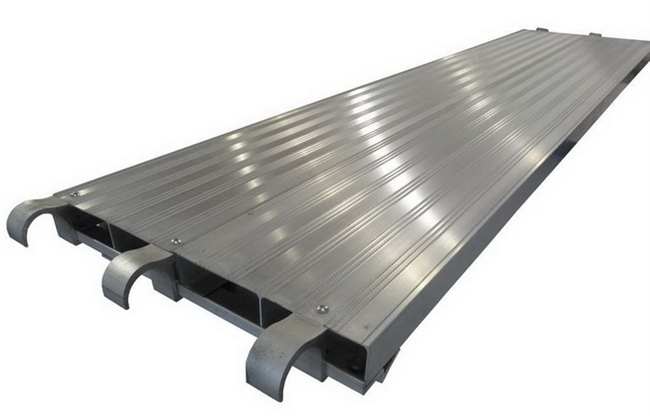

Aluminum Scaffold Plank: the perfect blend of strength, safety, and versatility for your construction needs. Engineered from premium-grade aluminum, this plank offers a lightweight solution without sacrificing durability. Its slip-resistant surface ensures maximum safety for workers, while the modular design allows for easy integration with various scaffolding systems. Ideal for a wide range of construction environments, our Aluminum Scaffold Plank is designed to elevate the efficiency and safety of your projects.

Areas

What is Aluminum Ringlock Scaffolding?

Aluminum Ringlock Scaffolding is a type of scaffolding that is made of aluminum 6082-T6 and uses a ringlock system to connect the components. The ringlock system consists of a series of rings that are welded to the standards and ledgers. The rings allow for quick and easy assembly and disassembly of the scaffolding.

It is a type of modular scaffolding material prefabricated with ring locks on vertical parts and cast aluminum ledger heads & brace heads on horizontals and diagonal parts.

Aluminum Ringlock system is a group of ringlock scaffolding parts and components, including aluminum ringlock standards, aluminum ringlock ledgers, aluminum diagonal braces, aluminum decks, etc, used to form scaffold frames and towers for construction and shoring.

Aluminum ringlock scaffolding is a popular choice for construction projects because it is lightweight, strong, and versatile. It can be used for a variety of applications, including:

- Construction Sites: For new builds and renovations where flexibility and time efficiency are crucial.

- Event Staging: Used in concerts and public events to create stages, lighting rigs, and other temporary structures.

- Industrial Maintenance: Ideal for use in plants and factories where corrosion resistance and weight considerations are important.

- Architectural Restoration: Useful in sensitive environments where traditional scaffolding might be too invasive or heavy.

In the ringlock scaffolding, wedge pins are fixed on the aluminum ring lock ledger and aluminum brace heads by rivets. It is used to fix ring system horizontals and braces between aluminum ringlock standards.

The rings on the aluminum ringock scaffolding standards are like rosette flowers. They are round and with 8 holes. The circled placed 8 holes allows 4 ringlock diagonal braces and 4 ringlock horizontals connected to the same verticals at the same time from 8 directions. That is why the ring system scaffold is the most versatile scaffold system. It can be used in all shapes of construction: rectangle, circle, angular, unregular shaped, etc.

EN Certifications Ensure Your Quality

When it comes to scaffolding, quality and safety are paramount. Scafotech’s aluminum ringlock scaffolding, backed by EN certifications, ensures your construction projects are safe, efficient, and compliant with industry standards. Trust Scafotech, a leading scaffolding manufacturer in China, to provide the reliable scaffolding solutions you need.

Packing

As a professional aluminum ringlock scaffolding manufacturer in China, we understand that top-quality products demand equally reliable packing. We ensure that your scaffolding arrives in perfect condition, ready for immediate use. Whether you are a contractor, scaffolding rental company, or wholesale distributor, you can trust that our packing will protect your products well.

Aluminum Ringlock Scaffold Specification:

Aluminum Ringlock Standard

Aluminum Ringlock scaffolding standards are vertical parts of ring system scaffold. They are fabricated by scaffold tubes, rosettes, and scaffold spigots. While the rosette rings are welded on the scaffold tube at every 500 mm (250mm is available too).

Ringlock standards are the most important parts of the ringlock scaffolding system. It gives connectors for other ringlock scaffolding parts like rinlgock horizontals, ringlock braces, side brackets, lattice girders & beams, ringlock bridging, etc.

According to the ringlock scaffolding standard sizes, you can find OD48mm ringlock standards and OD60mm ringlock standards.

OD48mm ringlock standards are used for lightweight required normal construction. While OD60mm ringlock scaffolding is also called heavy-duty shore system ringlock. They are used for heavy-duty load requirement shoring construction.

| Iteam | Material | Size | Surface |

|---|---|---|---|

| RSARS 050 | 6082-T6 48.3*4mm | 0.5m | Mill Finish |

| RSARS 100 | 6082-T6 48.3*4mm | 1.0m | Mill Finish |

| RSARS 150 | 6082-T6 48.3*4mm | 1.5m | Mill Finish |

| RSARS 200 | 6082-T6 48.3*4mm | 2.0m | Mill Finish |

| Contact us to know more |

Aluminum Ringlock Ledger

Ringlock ledgers are horizontal parts of the ring system scaffolding. Thus you can call it to ringlock horizontals.

Ringlock O ledgers are made by OD48.3mm standard scaffold tubes. At both ends of the ring lock O ledgers, two sets of ledger ends(heads) and wedge pins. The wedge pins are fixed on the ringlock ledgers by special rivets.

| Iteam | Material | Size | Surface |

|---|---|---|---|

| RSARL 073 | 6082-T6 48.3*3mm | 0.73m | Mill Finish |

| RSARL 104 | 6082-T6 48.3*3mm | 1.04m | Mill Finish |

| RSARL 109 | 6082-T6 48.3*3mm | 1.09m | Mill Finish |

| RSARL 157 | 6082-T6 48.3*3mm | 1.57m | Mill Finish |

| Contact us to know more |

Aluminum Diagonal Brace

Ringlock diagonal braces are a type of vertical brace for the ringlock scaffolding tower. The diagonal brace sizes are based on the bay of the ringlock horizontal and vertical sizes. In fabrication, it is made from OD48.3mm standard scaffold tubes with braced heads (left and right brace head) on both sides.

More than diagonal braces, there are horizontal braces to make the scaffold tower stable and take more load.

| Iteam | Material | Size | Surface |

|---|---|---|---|

| RSADB 073 | 6082-T6 48.3*3mm | 0.73*2m | Mill Finish |

| RSADB 104 | 6082-T6 48.3*3mm | 1.04*2m | Mill Finish |

| RSADB 109 | 6082-T6 48.3*3mm | 1.09*2m | Mill Finish |

| RSADB 157 | 6082-T6 48.3*3mm | 1.57*2m | Mill Finish |

| Contact us to know more |

Introduction Of Aluminum Ringlock Scaffolding?

Have you ever marvelled at the intricate network of scaffolding that envelops a building under construction? Ever wondered how these temporary structures support the weight of workers, materials, and even heavy machinery? Or how they adapt to complex architectural designs, providing access to the most hard-to-reach spots? The answer to these questions lies in the innovative design and material of the scaffolding system used. One such system that has revolutionized the construction industry is the Aluminum Ringlock Scaffolding, specifically made from 6082-T6 aluminum.

Aluminum Ringlock Scaffolding, crafted from 6082-T6 aluminum, is a modular scaffolding system that is known for its strength, versatility, and ease of assembly. The 6082-T6 aluminum is a high-strength, heat-treatable alloy that is resistant to stress and corrosion, making it an ideal material for scaffolding. This type of scaffolding uses a simple ringlock mechanism for connecting various components, making it adaptable to a wide range of construction scenarios. Its unique design allows for quick assembly and dismantling, saving valuable time on the construction site. Whether it’s a residential building, a commercial complex, or a large-scale infrastructure project, Aluminum Ringlock Scaffolding provides a reliable and efficient solution for construction needs.

The Anatomy of Aluminum Ringlock Scaffolding

Aluminum Ringlock Scaffolding is composed of several key components that work together to provide a sturdy and reliable structure. These include:

Standards or Verticals: These are the vertical components made of 6082-T6 aluminum that provide the main support for the scaffolding structure. They come with ringlock rosettes at regular intervals for connecting other components.

Ledgers or Horizontals: These are the horizontal components that connect the standards. They provide lateral support to the structure and also serve as a support for the working platform.

Diagonal Braces: These components provide diagonal support to the structure, enhancing its stability and rigidity.

Base Collars and Adjustable Bases: These components provide a solid foundation for the scaffolding, ensuring it remains stable and level, even on uneven ground.

Work Platforms: These are the surfaces upon which workers stand or materials are placed. They are typically made of wood or metal and are supported by the ledgers.

The Benefits of Aluminum Ringlock Scaffolding

The Aluminum Ringlock Scaffolding system offers several benefits that make it a preferred choice for many construction projects:

1. Strength and Durability:

Why Aluminum Ringlock Scaffolding Is Considered Strong

Despite aluminum’s lower absolute strength compared to steel, modern alloys enhance its strength sufficiently to meet structural requirements. Alloys such as 6061 (aluminum-magnesium-silicon) and 7075 (aluminum-zinc-magnesium-copper) are particularly noted for their robust mechanical properties. Aluminum’s ability to endure loads and resist breaking under stress, thanks to its favorable strength-to-weight ratio, makes it a sturdy option for scaffolding.

The 6082-T6 aluminum used in the construction of this scaffolding system is known for its high strength and durability. It can withstand heavy loads and harsh environmental conditions, ensuring the safety of workers and the integrity of the structure.

2. Lightweight:

Aluminum has a density of approximately 2.7 g/cm³, significantly lower than steel’s density, which stands around 7.85 g/cm³. This substantial difference means that aluminum is about one-third the weight of steel. The lower density of aluminum makes aluminum scaffolding far lighter than its steel counterparts.

Specific Advantages of Being Lightweight

- Reduced Transportation Costs: The reduced weight allows for more scaffolding to be transported at the same cost, decreasing logistical expenses.

- Ease of Assembly and Disassembly: Aluminum scaffolding can be set up and taken down more quickly and with less labor than heavier materials. This not only speeds up project timelines but also reduces labor costs.

3. Versatility:

The ringlock system allows for the easy and quick connection of various components, making it adaptable to a wide range of construction scenarios. Whether it’s a simple, straight wall or a complex structure with multiple angles, Aluminum Ringlock Scaffolding can accommodate it.

Corrosion Resistance: Aluminum is naturally resistant to corrosion, which means the scaffolding can withstand exposure to the elements without losing its strength or integrity. This makes it ideal for use in all kinds of weather and environmental conditions.

4. Safety:

Reasons for Aluminum Scaffolding Being Safe

- Structural Stability: The ringlock joint design in aluminum scaffolding systems provides high stability. This setup ensures that connections are secure even under high loads, which is crucial for worker safety.

- Corrosion Resistance: Unlike steel, aluminum naturally resists rust and corrosion without the need for additional treatments like galvanizing. This inherent property reduces maintenance needs and prolongs the scaffolding’s lifespan, enhancing safety over time.

5. Additional Advantages Over Steel Scaffolding

- No Need for Galvanization: Steel typically requires galvanization to prevent rust, which adds to the cost and environmental impact. Aluminum does not require such treatments, offering a cost-effective and environmentally friendly alternative.

- Environmental Sustainability: Aluminum is easier to recycle than steel and the recycling process is less energy-intensive. This makes aluminum scaffolding a more sustainable choice, aligning with the growing emphasis on environmental responsibility in the construction industry.

Conclusion

In conclusion, Aluminum Ringlock Scaffolding, made from 6082-T6 aluminum, is a robust, versatile, and efficient solution for a wide range of construction needs.

FAQs

What is Aluminum Ringlock Scaffolding? Aluminum Ringlock Scaffolding is a modular scaffolding system known for its strength, versatility, and ease of assembly. It’s made from 6082-T6 aluminum, a high-strength, heat-treatable alloy that is resistant to stress and corrosion.

What are the components of Aluminum Ringlock Scaffolding? The main components of Aluminum Ringlock Scaffolding include standards or verticals, ledgers or horizontals, diagonal braces, base collars and adjustable bases, and work platforms.

What are the benefits of Aluminum Ringlock Scaffolding? The benefits of Aluminum Ringlock Scaffolding include its strength and durability, lightweight nature, versatility, and corrosion resistance.

What is 6082-T6 aluminum? 6082-T6 aluminum is a high-strength, heat-treatable alloy that is resistant to stress and corrosion. It’s an ideal material for scaffolding due to its strength and durability.

Can Aluminum Ringlock Scaffolding be used for complex structures? Yes, the ringlock system allows for the easy and quick connection of various components, making it adaptable to a wide range of construction scenarios, including complex structures with multiple angles.

Applications of Aluminum Ringlock Scaffolding

Aluminum Ringlock Scaffolding is not just versatile in its construction, but also in its applications. Here are a few scenarios where this scaffolding system proves to be invaluable:

Building and House Construction: From small houses to large commercial buildings, Aluminum Ringlock Scaffolding provides a safe and efficient working platform for workers. Its high load-bearing capacity and stability make it suitable for all types of construction work.

Bridges and Highways: In infrastructure projects like bridges and highways, the scaffolding system needs to be strong, stable, and adaptable to various conditions. Aluminum Ringlock Scaffolding meets all these requirements, making it an ideal choice for such projects.

Ship Building: The construction and repair of ships require a scaffolding system that can adapt to the unique shapes and structures of ships. Aluminum Ringlock Scaffolding, with its flexible and modular design, is well-suited for this task.

Maintenance and Repair Work: Whether it’s the maintenance of buildings, bridges, or industrial plants, Aluminum Ringlock Scaffolding provides a safe and stable platform for workers to carry out their tasks.

ScafoTech’s Approach to Aluminum Ringlock Scaffolding

At ScafoTech, we understand the importance of reliable, efficient, and adaptable scaffolding systems. That’s why we offer products that align with the benefits of Aluminum Ringlock Scaffolding. Here’s what sets us apart:

Quality and Compliance: All our products are certified by TUV, SGS, OSHA, and ANIS, ensuring that they meet international safety and quality standards. We use high-quality 6082-T6 aluminum for our scaffolding systems, ensuring their strength and durability.

Customization: We understand that every construction project is unique. That’s why we offer customized solutions to meet your specific needs. Our team of experienced engineers can design and develop unique scaffolding systems that meet the highest industry standards.

Conclusion

In conclusion, Aluminum Ringlock Scaffolding, made from 6082-T6 aluminum, is a robust, versatile, and efficient solution for a wide range of construction needs. Whether you’re constructing a building, a bridge, or a ship, or carrying out maintenance work, this scaffolding system can provide a safe and efficient working platform. And when you need a scaffolding system that’s tailored to your specific needs, remember that ScafoTech is here to help.

Get Access Now: scafotech.com

This concludes the article on Aluminum Ringlock Scaffolding. The aim was to provide a comprehensive understanding of what Aluminum Ringlock Scaffolding is, its components, benefits, applications, and how ScafoTech’s approach aligns with these aspects. The information provided should help readers make informed decisions when it comes to choosing the right scaffolding system for their construction needs.